Introduction

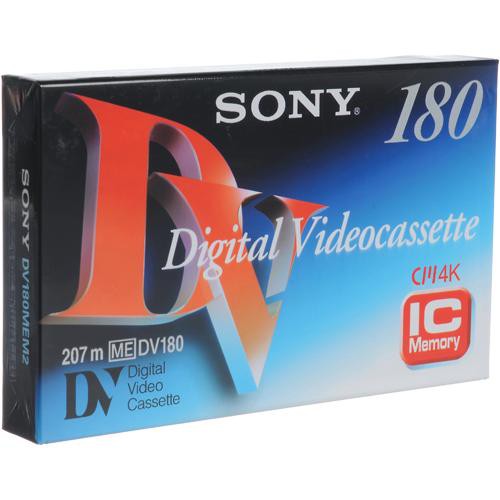

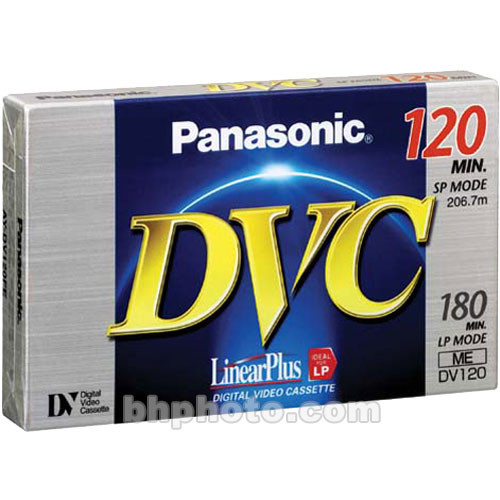

Standard DVC (Digital Video Cassette) is a digital video cassette format that utilizes the DV encoding standard. According to the DV encoding standard, video must be recorded using 6.35 mm (1/4 inch) magnetic videotape. However, any size cassette can be used to house DV tape. Originally, DV cassettes were available in two sizes: Standard DVC and MiniDV. Most DV camcorders available on the consumer market were compatible with either Standard DVC or MiniDV cassettes. Some professional equipment, such as the JVC Professional DV camcorder, could accommodate both cassette sizes. DVC cassettes are larger and can record more video than MiniDV cassettes (3.5 - 4 hours of compared to 60 minutes), however MiniDV cassettes quickly became more popular among consumers due to their small size and portability.

Identification

Image source

Physical Characteristics

| Tape width | ¼ inch (6.35mm) |

|---|---|

| Tape composition | Metal evaporate (ME) |

| Cassette dimensions | 97.5 × 64.5 × 14.6 mm |

| Identifying features | Cassettes labeled with DV or DVC |

| Common manufacturers/brands | Sony, Panasonic, JVC |

| Playback |

|

Technical Characteristics

| Record time | Standard play: 3 hrs Long play: 4.6 hrs |

|---|---|

| Track pitch | Standard play: 10 microns Long play: 6.7 microns |

| Track width | Standard play: 10 microns Long play: 6.7 microns |

| Record/playback speed | Standard play mode: 18.81 mm/sec |

| Bitrate | 25 Mbit/s |

| Bit depth | 8 bit |

| Colour sampling | PAL: 4:2:0 NTSC: 4:1:1 |

| Resolution | PAL: 720x576 |

| Compression | 5:1 DVC-format DCT compression (intra-frame) |

Technical standards

- Society for Motion Picture Technical Engineers (SMPTE) standard for television 314M Data structure for DV-based audio, data and compressed video – 25 and 50 MB/s. The differences between IEC 61834-5 and SMPTE 314M are shown in Annex A of SMPTE 314M.

Storage

| Storage environment: temperature | Ideal: 40–54°F (4.5–12°C) Acceptable: 55–60°F (13–15.5°C) |

|---|---|

| Storage environment: humidity | 30–50% RH |

| Container | DVC containers should pass the Photographic Activity Test (PAT) as specified ISO Standard 18916:2007

Containers are acceptable if they:

Unacceptable containers must be replaced with clean, inert containers. |

| Orientation of tape in storage | Vertical on its end (like books) |

Types of damage and deterioration

Binder deterioration

Image source

"1.1.3. Inspect for damage / Look for chemical deterioration / Binder degradation". In Audio Tape Digitisation Workflow. Accessed February 22, 2021.

Description

Commonly known as "sticky shed syndrome." Affected records will have a visible gummy or powdery residue on the surface of the tape. This can damage both the recorded material and playback equipment. Back-coated tapes are most affected by this type of deterioration.

Cause

Polyester urethane is prone to moisture absorption which can cause the molecular structure of the binder to break down. This process is accelerated by high temperature and high humidity.

Remedy

Environmental conditioning: Moving the tape to a controlled storage environment (40°C / 20 to 25% Relative Humidity) may reverse the affects of hydrolysis over time.

Baking: Holding the tape at an elevated temperature (45°C to 55°C) for a brief period of time (up to 36 hours) can temporarily remove moisture and allow normal playback for a period of one to two weeks. Tapes should not be rewound before baking.

Drop-out

Image source

"1.1.3. Inspect for damage / Look for chemical deterioration / Binder degradation". In Audio Tape Digitisation Workflow. Accessed February 22, 2021.

Description

A brief signal loss caused by a tape head clog, missing magnetic oxide particles, tape defect, or debris on the tape or machine. These factors can reduce head-to-tape spacing and result in the appearance of white spots or streaks on playback. Multiple drop-outs per frame will result in a snowy appearance.

Cause

Tapes kept in dusty conditions will accumulate particulate matter, increasing the risk of drop-out.

Remedy

Flaking/missing magnetic oxide particles are an indication of tape deterioration. This type of drop-out cannot be corrected physically.

Mould

Description

Active mould is generally moist while dormant mould is dry and dusty. Mould growths may be white, black, brown or mustard-coloured and usually have a pattered, fuzzy, or thread-like appearance. Mould can cause permanent damage to tapes over time if not removed. Fungus and mould is also a significant health hazard and affected materials should be handled using gloves and masks.

Cause

Storing tapes at high temperature and relative humidity levels can facilitate the growth of mould.

Remedy

Mouldy tapes should be isolated from unaffected materials to prevent cross contamination. Store tapes at a temperature of 24°C in an environment with effective air circulation and less than 50% Relative Humidity. Loose mold can be vacuumed from the tape pack and then the tape should be treated with an appropriate fungicide.

Stretching and breaking

Cause

Stretching and breaking of video tape usually results from improper handling or use of playback equipment.

Remedy

Stretching can distort the tape signal however data can usually be recovered (with a decrease in signal quality).

Accidental recording

Description

Camera operators can accidentally record over pre-existing footage

Cause

Tape is set to "record mode" when it is inserted into camera or deck

Remedy

Ensure tape is set to "safe mode" before inserting into camera or deck.

Risk assessment

HIGH RISK

Digital video material stored on magnetic videotape is considered to be at high-risk of loss or degradation.

Polyester base film used in videotape is considered very stable.

Other components of the videotape, including the binder, are considerably less stable and are more likely to be the cause of degradation.

Format obsolesce, including lack of well-functioning playback equipment poses an equal or even greater risk than degradation, even with higher quality formats such as Digital Betacam

Archivists should appraise or reappraise digital video material stored on magnetic tape to determine the nature and significance of video elements contained on the tape. See Section 5 of the University Archives Procedure Manual for guidance on appraising sound recordings and moving images.

The archival appraisal should determine whether the video elements have sufficient archival value to justify reformatting and long-term preservation as digital video files.

Related resources

- Section 9.0 - Outsourced digitization of audiovisual items

- Appendix C - Technical specifications for moving images

University Archives Procedure Manual

Further Reading

Visit the /wiki/spaces/ALC/overview for further reading on /wiki/spaces/ALC/pages/1891631115.

References

AMIA. "Video Preservation Factsheets." Accessed December 10, 2020.

Bensinger, Charles. "Chapter 6: All about videotape." In The Video Guide, Second Edition, 71-75. Santa Barbara, California: Video-Info Publications, 1981.

Bogart, John Van. "What Can Go Wrong With Magnetic Media?" In Magnetic Tape Storage and Handling: A Guide for Libraries and Archives. Washington, DC: The Commission on Preservation and Access, 1995.

Casey, Mike. "FACET: Format characteristics and preservation problems." Bloomington, IN: Indiana University, 2007.

Gibson, Gerald. D. "Magnetic tape deterioration: recognition, recovery and prevention." Paper presented at the IASA Conference, Perugia, August 26, 1996.

Jones, Gerald Everett and Pete Shaner. "DV Technology and the Camcorder." In Real World Digital Video. Second Edition. Peachpit Press, 2005.

JVC Victor Company of Japan Limited. "Professional DV." Accessed February 2, 2021.

MediaCollege.com. "DV video." Accessed February 2, 2021.

Nielsen, Rebecca. "Media Recognition: DV Part 2." Bodleian Libraries. March 26, 2012.

Wheeler, Jim. "Videotape preservation handbook." 2002.

Wilt, Adam J. "The DV, DVCAM & DVCPRO Formats: The DV formats tabulated." August 28, 2005.

Wilt, Adam J. "The DV, DVCAM & DVCPRO Formats." July 16, 2006.

Version history

| Version | Date | Author(s) | Version Notes |

|---|---|---|---|